Image Source: Google

Grinding processes are crucial in various industries such as automotive, aerospace, and machinery manufacturing. The quality and efficiency of these processes can significantly impact the final product's performance and durability. To achieve optimal results, it is essential to use the right tools and technologies. Metal bond wheels have emerged as the ultimate tool for revolutionizing the grinding process, offering unmatched efficiency and precision. Refer: https://www.cdtusa.net/metal-bond.

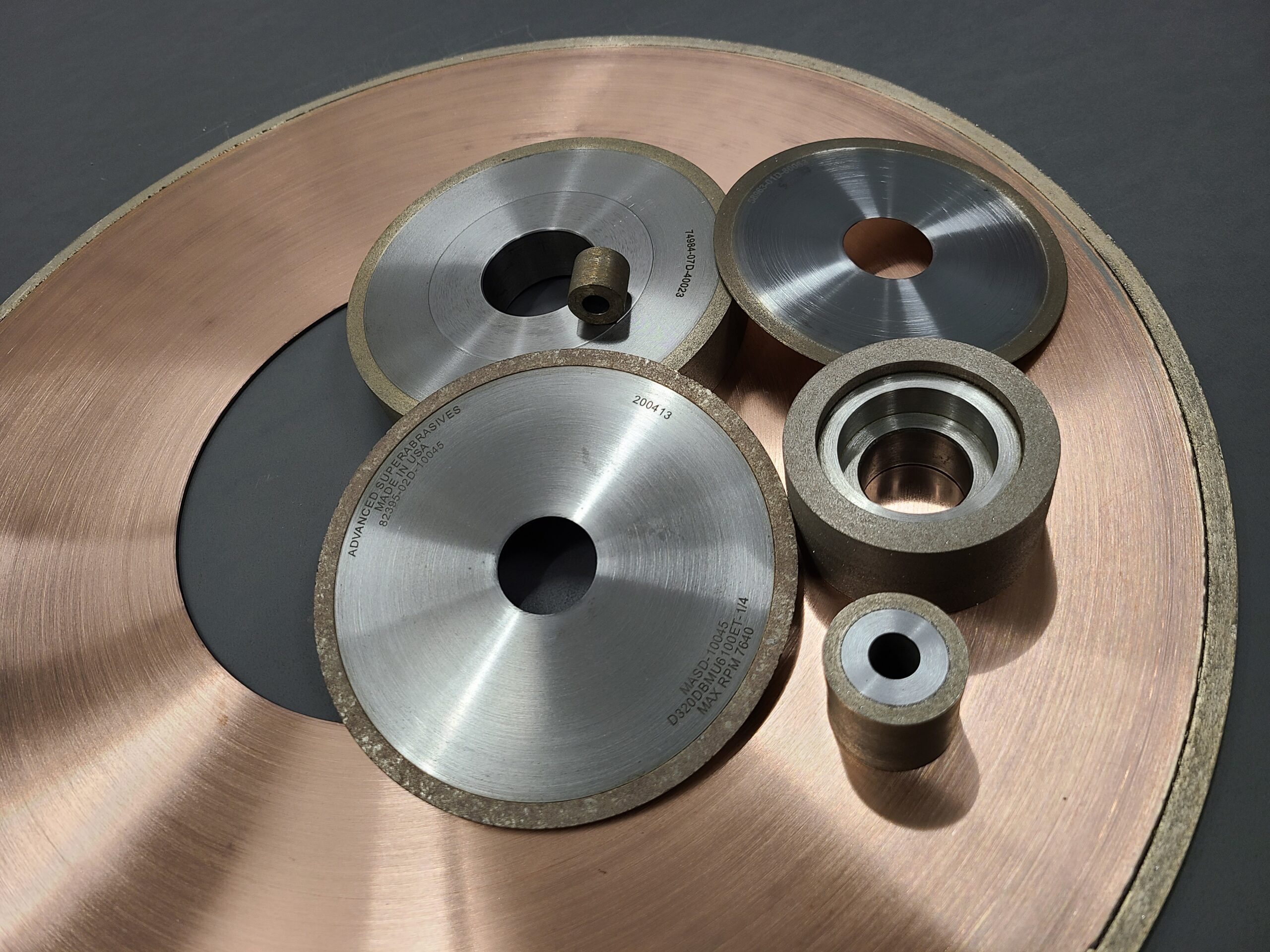

Metal bond wheels are made from a mixture of metal powders, diamond particles, and other fillers. The metal powder is bonded together to form a matrix that holds the diamond particles in place. This unique composition gives metal bond wheels their exceptional hardness, durability, and cutting ability. Compared to other types of grinding wheels, metal bond wheels offer superior performance in terms of material removal rate, tool life, and surface finish quality.

One of the key advantages of metal bond wheels is their long lifespan. The metal matrix provides excellent support for the diamond particles, allowing them to maintain their sharpness and cutting ability for an extended period. This results in longer tool life and reduced downtime for wheel changes, leading to increased productivity and cost savings for manufacturers. Additionally, the consistent performance of metal bond wheels ensures a high level of accuracy and precision in the grinding process.

Another significant benefit of metal bond wheels is their versatility. They can be customized to meet specific grinding requirements, such as material type, hardness, and desired surface finish. This flexibility allows manufacturers to achieve optimal results across a wide range of applications, from rough grinding to fine finishing. Whether grinding hard materials like ceramics and carbides or softer materials like aluminum and composites, metal bond wheels deliver consistent and reliable performance.

Furthermore, metal bond wheels are highly efficient in removing material and achieving high stock removal rates. The aggressive cutting action of the diamond particles combined with the rigid metal matrix allows for fast and efficient grinding, reducing cycle times and increasing throughput. This is particularly beneficial for manufacturers looking to improve their overall operational efficiency and meet tight production deadlines.

When it comes to surface finish quality, metal bond wheels excel in producing smooth, uniform surfaces with minimal subsurface damage. The precise control over the grinding process, coupled with the ability to maintain sharp cutting edges, results in superior surface integrity and dimensional accuracy. This is essential for applications where surface roughness and flatness are critical factors, such as in precision machining and tool making.

In addition to their performance benefits, metal bond wheels also offer environmental advantages. The use of diamond abrasives in metal bond wheels results in less heat generation and lower energy consumption compared to conventional abrasive materials. This not only reduces the carbon footprint of the grinding process but also extends the lifespan of the machine and reduces maintenance costs.

Overall, metal bond wheels have revolutionized the grinding process by providing manufacturers with a high-performance tool that offers unmatched efficiency, precision, and versatility. Whether you are looking to improve productivity, enhance surface finish quality, or reduce tooling costs, metal bond wheels can help you achieve your goals. With their long lifespan, fast stock removal rates, and superior surface finish capabilities, metal bond wheels are the ultimate tool for driving efficiency and success in your grinding operations.

As technology continues to evolve and industries demand higher levels of performance and quality, metal bond wheels will remain at the forefront of grinding technology. Their unique combination of hardness, durability, and cutting ability makes them an indispensable tool for manufacturers seeking to stay ahead of the competition. By investing in metal bond wheels, you can revolutionize your grinding process and take your manufacturing operations to the next level of efficiency and success.